Posted: December 13, 2022

Banner: IEA SHC Task 64

It is generally a big challenge to contract and design solar industrial heat projects (SHIP). The IEA Solar Heating and Cooling Task 64 on Solar Process Heat aims at supporting planners and investors, to stimulate market growth. In the most recent IEA SHC Solar Academy webinar, three task experts shared their tips and tricks regarding design and success factors for SHIP. Here, we present selected aspects from the 1.5-hour training session. The full recording including the Q&A session is available here.

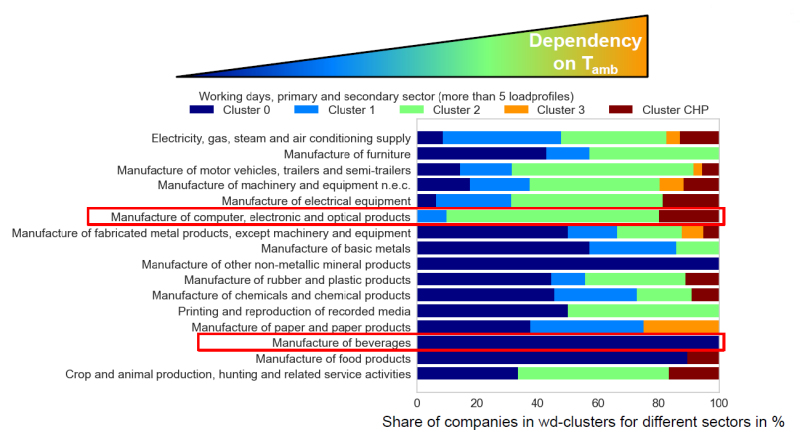

Felix Pag from the University of Kassel, Germany, spoke about the role of solar in future industrial hybrid energy systems. Based on the analysis of measured heat profiles from several hundred industrial companies in Germany, he was able to show the sectors in which there is a strong dependency of the heat load profile on the ambient temperature. In figure 1, for example, a manufacturer of beverages is put into the cluster without any seasonal behaviour, whereas manufactures of computer, electronic and optical products have more processes which are related to the ambient temperature. “It is very important to consider the seasonal behaviour of the heat load during the design phase”, Pag recommended. The good news for SHIP: there are almost no companies without summer heat demand which can be covered with solar collectors.

Figure 1: Proportions of companies with a certain load profile during working days within a particular industry segment. Example: Among the manufacturers of beverages 100 % are in cluster 0, whereas in other sectors there is a bigger spectrum

Source: University of Kassel / Paper

Cost assessment of hybrid renewable industrial heat systems

“At the beginning of the task we noticed that everybody was talking about the combination of solar and heat pumps, but there is no really established common system design methodology and each planner has their own strategy based on individual experience”, said Pag. So the researchers from the University of Kassel investigated three different system designs. They wanted to find out which parameters influence the levelised cost of heat of such hybrid systems. They compared firstly a parallel configuration where the heat pump and the solar field provide the required temperature together in parallel, secondly a variant where solar pre-heats the water and thirdly a configuration where the heat pump is the pre-heater.

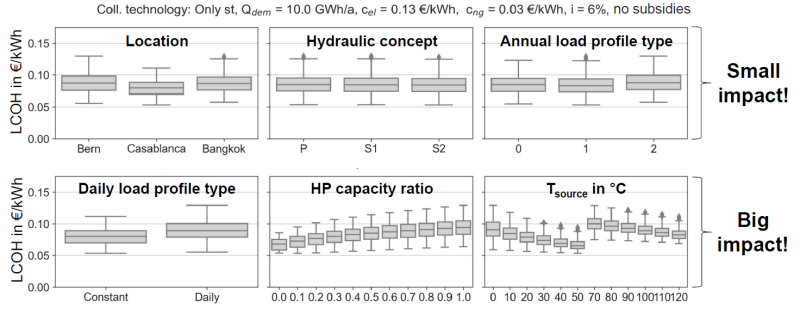

Figure 2: Parameters impacting the levelised cost of heat of hybrid SHIP systems calculated over 20 years (6 % discount rate) based on fixed energy costs with a level from before the energy crises

Source: University of Kassel

The researchers found that the location, the hydraulic concept and the load profile type have very little impact on the economics of the system (top part on figure 2) whereas the other three parameters at the bottom of figure 2 really make a difference to the levelized cost of heat (LCOH). Among them are the daily load profile and the temperature of the heat pump’s heat source.

In figure 2 you can also see that the heat pump capacity ratio, which is defined as the heat pump capacity divided by the maximum heat load of the factory, influences the economics significantly. “Our calculations have shown that a strong under-dimensioning of the heat pump results in lower LCOH, but the smaller the heat pump the lower the renewable proportion that you achieve over the year”, said Pag. He concluded that the heat pump capacity factor should be around 0.5 to find a good trade-off between lower LCOH and a reasonably high renewable energy fraction. In this variant the capacity of the heat pump is half of the total peak heat load of the factory.

More details about the results of the LCOH assessment will be published in a paper titled Hybrid Solar Thermal and Heat Pump Systems in Industry: Model Based Development of Globally Applicable Design Guidelines, which is currently under review at Solar Energy Advances.

Three success factors for SHIP

Wolfgang Gruber-Glatzl from AEE INTEC, Austria, introduced some of the success factors for SHIP based on the project database www.ship-plants.info which includes more than 400 plants worldwide. He took the perspective of the end user. Investors want to know if SHIP is a reliable solution, whether it is a simple solution and if they will be the first ones to implement it or if it has been done before. “Once we have convinced the end user that SHIP is reliable and that there are experts with a lot of experience, the next important selling point is the constant and low heat prices”, he said.

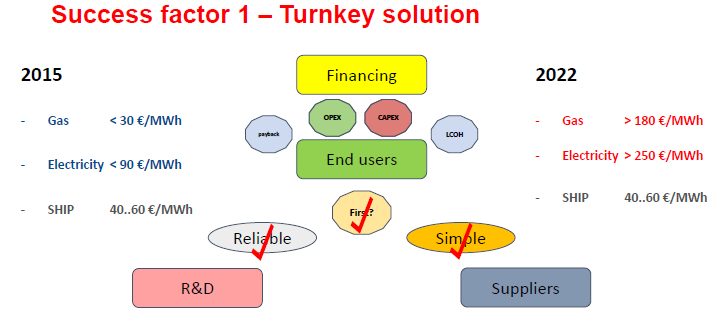

Success factor 1: Turnkey solutions

“We try to avoid looking at payback times because they do not show the true value of solar industrial heat”, said Gruber-Glatzl. “Better is to change the perspective towards levelised cost of heat to illustrate the long-term energy security providing heat at reasonable costs.” Hence his first success factor is a business model that establishes customer confidence by delivering solar heat instead of selling the collector field. As an example of a successful ESCO (stands for energy service company), Gruber-Glatzl cited the 10 MW plant for the malt factory in southern France that started operation in the first half of 2021.

596 m2 vacuum flat plate collectors at the beverage factory of Martini & Rossi in Northern Italy Photo: TVP Solar

Success factor 2: Innovation

Whereas a high number of SHIP plants so far have been installed using flat-plate collectors, Gruber-Glatzl sees an increasing trend towards SHIP systems that provide higher temperatures above 100 °C either with evacuated flat-plate collectors or parabolic trough collectors. Their big advantage is that these collector fields can be integrated into the supply line on the utility side of the industrial plant. “In this case you are talking to the Facility Manager and not to the Production Manager and you can actually provide a larger proportion of the heat demand and achieve economies of scale”, said Gruber-Glatzl. He thinks the next stage of innovation will be hybrid solutions together with heat pumps and seasonal storage, also combined with sources of exceed heat.

Success factor 3: Multiplication, standardisation

For his last success factor Gruber-Glatzl looked to Mexico - the largest SHIP market in terms of number of installed systems worldwide, where two dominating technology suppliers have optimised their selling points. They have reduced their planning costs by standardisation because they keep realising similar integration schemes. Furthermore, they have been in contact with many industrial customers and know their needs. This high replicability makes their solutions competitive, summarised the Austrian researcher. “It is very important that other SHIP solution providers also reach this tipping point to accelerate their business. That will provide the opportunity of snowballing the SHIP market, also in other regions”, he concluded.

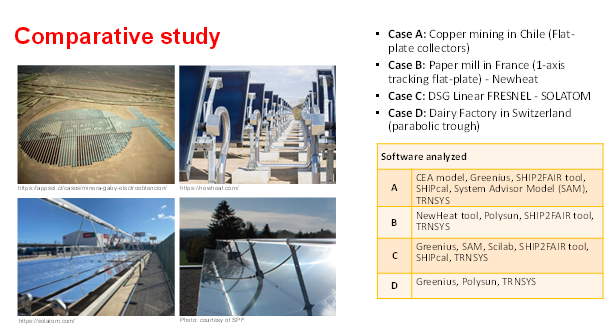

Alan Pino from the University of Seville spoke about the comparison study of different simulation tools for yield assessment of SHIP plants. He announced the publication of the Guideline for yield assessment in SHIP plants that will be published in the first quarter of 2023. We will report on this in a separate news article.

Source: University of Seville

Organisations mentioned in this news article: